Vax system set to deliver

Australian researchers have developed new technology to deliver vaccines for more cheaply and efficiently.

Australian researchers have developed new technology to deliver vaccines for more cheaply and efficiently.

The new approach has taken the world’s first and most successful vaccine against small pox - genetically altered it to improve its safety and efficacy - and created a new vaccine platform able to deliver multiple antigens to guard against serious infectious diseases, including the mosquito-borne zika and chikungunya viruses.

The new vaccine has been tested in preclinical proof of concept studies and been shown to provide protection against Chikungunya infection and its virus-induced complications and Zika virus – importantly preventing transmission of the virus to the foetus in pregnancy and also persistent infection of the testis.

Details of the new technique have been published in the journal Nature Communications.

“We have now proved this is a very effective delivery vehicle for a vaccine protecting against multiple infectious diseases,” says UniSA researcher Professor John Hayball says.

“Working together, we will continue to explore the potential of this platform to deliver multiple disease vaccines.

“This work puts us well on the way to delivering health benefits to millions of people around the world by providing more effective and accessible vaccines.

“The potential applications of this Australian research for a range of diseases and other conditions is enormous.”

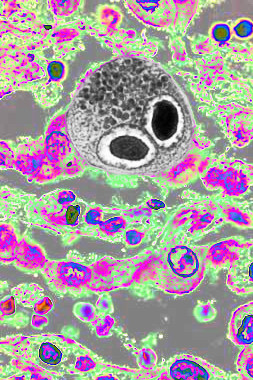

The project was undertaken in partnership with Sementis using Chinese Hamster Ovary (CHO) cells, which are routinely used for large scale manufacturing of biopharmaceuticals.

Sementis chair Maurice O'Shannassy says the production of a viral-vectored vaccine in a CHO cell substrate is a game-changer in terms of the improved economics of vaccine production and providing vaccines on a global scale.

“Previous vaccinia-based vaccine vector systems have used chicken embryo fibroblasts for manufacture, which is associated with a number of manufacturing and safety issues,” he says.

“Being able to manufacture a vectored vaccine using CHO cells is a world first and offers a number of advantages in the event of an outbreak, including rapid manufacture scale-up and cold chain (refrigeration) independent distribution capacity.”

Print

Print