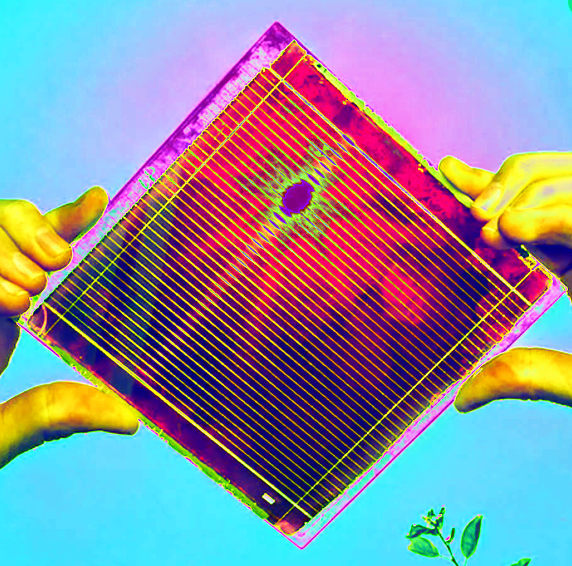

Photo flash spots solar flaws

A literal “trick of the light” has been used to detect imperfections in next-gen solar cells.

A literal “trick of the light” has been used to detect imperfections in next-gen solar cells.

On small scales, next-generation perovskite solar cells are already almost as efficient as silicon ones, but the material they are made of is much cheaper and more abundant than silicon.

However, as scale increases the perovskite cells perform less well, because of nanoscale surface imperfections resulting from the way they are made.

As the number of unwanted tiny lumps and bumps grows, the amount of solar power generated per square centimetre drops off.

Now, however, Australian researchers have come up with a solution – using a camera.

It turns out that critical imperfections invisible to the naked eye can be detected by shining blue light onto the cells and recording the infrared light that bounces back.

The technique employs a property of solar cells called “photoluminescence”.

This is the process by which an electron inside a molecule or semiconductor is briefly powered-up by an incoming photon. When the electron returns to its normal state, a photon is spat back out.

Microscale flaws alter the amount of infrared produced. Analysing how the extent of the light emitted from the solar cell varies under different operating conditions gives clues to how well the cell is functioning.

“Using this technique, we can rapidly identify a whole range of imperfections,” says Dr Kevin Rietwyk, an Exciton Science researcher based at Monash University.

“We can then figure out if there are enough of them to cause a problem and, if so, adjust the manufacturing process to fix it. It makes for a very effective quality control method.”

Equivalent checking methods are common in silicon cell manufacture. By employing an innovative light modulation, Dr Rietwyk and colleagues have designed a new approach that rises to the challenges posed by next-gen cells – opening a pathway to a scalable and potentially commercial device.

“This research shows clearly that the performance of perovskite solar cell devices is influenced by the number of small imperfections in the cells themselves,” said Professor Udo Bach, also of Exciton Science and Monash University.

“Using light modulation to find these flaws is a quick and robust way to solve the problem – and one that should work on any level of production.”

Print

Print