New metal brings big boost on nano-scale

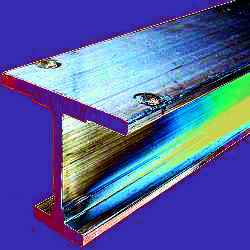

Material scientists have developed a new kind of light-weight steel that is as strong as titanium.

Material scientists have developed a new kind of light-weight steel that is as strong as titanium.

A team at Pohang University of Science and Technology in South Korea says it has come up with one of the biggest breakthroughs in decades: an entirely new type of flexible, ultra-strong, lightweight steel.

The new metal has a strength-to-weight ratio on par with even the highest-grade titanium alloys, but can be produced at one tenth of the cost.

In fact, engineers say, the new steel can be forged with machinery already used to make automotive-grade steel.

The study appears in the journal Nature.

Researchers discovered in the nineteen-seventies that adding aluminium to the mix when making steel could produce an incredibly strong and lightweight metal, but the end product was so brittle that it was considered useless.

The problem was that the aluminium-steel alloy contained fused atoms of aluminium and iron in crystalline structures called ‘B2’ – which are both strong and brittle.

Pohang University’s Dr Hansoo Kim says the latest efforts overcame this quandary.

“My original idea was that if I could somehow induce the formation of these B2 crystals, I might be able to disperse them in the steel,” Kim says.

The team worked out that if small B2 crystals were spread out enough, then the surrounding alloy would protect them from splintering.

They spent years honing a method of heat-treating and then thinly rolling the steel to control the formation of B2 crystals, and discovered that adding a sprinkling of nickel allowed them even more control over B2 formation.

The final product “is 13 percent less dense compared to normal steel, and has almost the same strength-to-weight ratio compared to titanium alloys,” Kim says.

The new material is very promising, but can only be made on a small scale.

Before it can go into mass-production, the researchers must confront an issue with the industry.

At the moment, steelmakers use a silicate layer to protect the metal from oxidation and contamination, but this silicate reacts with cooling aluminium, making it unsuitable for Kim’s new steel.

The big challenge is now to find a way to protect the material in the real world.

Dr Kim says that while the results are exciting, the method is the important part.

Now that the latest work on B2 crystal dispersion has been published, he says he hopes to see many new projects to develop similarly innovative metals based on the same method.

Print

Print