Plastic probed for new polymers

Australian researchers are working on new polymers made from waste sulphur.

Australian researchers are working on new polymers made from waste sulphur.

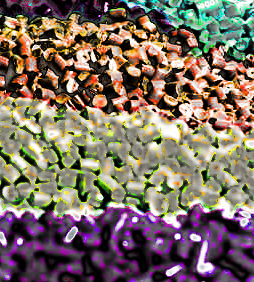

Many modern plastics, rubbers and ceramics cannot be recycled, but sulphur-based materials are showing promise to solve one of the planet’s biggest recycling problems.

Sulfur polymers are already being used in next-generation batteries, IR imaging (such as night-vision lenses), environmental remediation, and agriculture, but it has been difficult to control the hardness, flexibility, colour and other key properties of these polymers.

Now, a Flinders University study has laid out design principles that can better control the properties of these polymers, making them more adaptable and attractive for other types of manufacturing.

The team wanted to identify which chemical building blocks impart which properties to the polymer.

For instance, making a polymer from sulphur, used canola oil and another low-cost industrial byproduct dicyclopentadiene (DCPD) can create several different types of materials. Add more canola oil, and it becomes a soft rubber. Add more of the rigid dicyclopentadiene molecule and the material becomes harder and more durable.

As another example, various polymers made from sulphur, limonene (a byproduct of the citrus industry) and DCPD at different ratios resulted in durable materials varying from soft waxes to hard glass all easily moulded into various shapes.

Also, adding terpinolene (an essential oil found in allspice and other plant products) to the sulphur polymer turned from orange to red to black while the DCPD more shape persistent at higher temperatures.

The researchers found the new polymers can be broken down and reformed into new materials, representing a new era in recyclable materials made from renewable building blocks such as plant oils and industry byproducts such as sulphur.

“Almost every household item has some kind of polymer (plastic) in them and making polymers from sulphur not carbon opens doors into a new frontier of possibilities, with some applications yet to be found,” says researcher Dr Tom Hasell.

“So far these new polymers have potential applications in lenses for thermal imaging, making high-capacity batteries more stable to repeated charge/discharge, and filters to remove toxic heavy metals from water.

“With sulphur is so readily available, sulphur polymers could also find application in bulk applications in construction, especially where thermal insulation, electrical insulation, and chemical resistance are important.”

Print

Print