Glass printing with normal gear

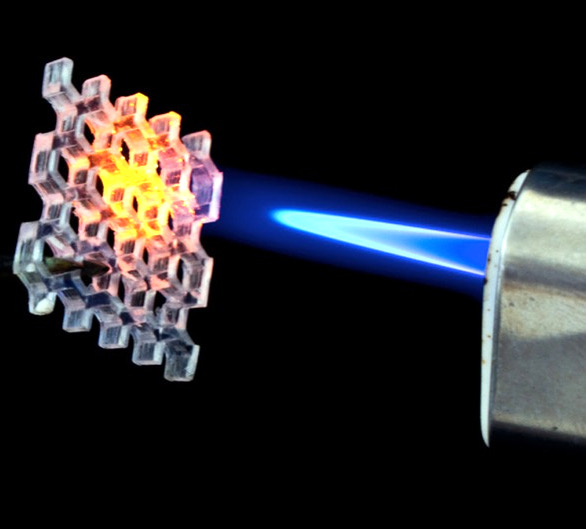

New techniques are allowing high-quality, intricate shapes made of glass to be manufactured using standard 3D printing technology.

New techniques are allowing high-quality, intricate shapes made of glass to be manufactured using standard 3D printing technology.

While researchers have demonstrated the method by making tiny glass castles and pretzels, they say it can produce structures of high optical quality suitable for the design of complex lenses and filters.

Glass has a number of useful properties, including electrical and thermal insulation, and unmatched optical transparency.

Creating bespoke structures, especially from high-purity glasses such as fused silica glass, is difficult due to the need for high processing temperatures and/or harsh chemicals.

The new technique, devised by Bastian Rapp and colleagues, overcomes this issue by using a free-flowing silica nanocomposite called ‘liquid glass’ in a standard 3D printer to produce complex shapes that are then heat-treated to produce optical-quality, fused silica glass structures.

These structures are smooth, transparent, and have features as small as a few tens of micrometres.

The new technique produces surfaces with sufficient clarity and reflectivity for a range of optical applications, making one of the oldest known materials accessible to twenty-first-century 3D-printing techniques.

The process is detailed in a paper published in Springer Nature.

Print

Print