Local tech saves US patient

A patient in the US has become the first to receive a high-tech new heart valve developed in Australia.

A patient in the US has become the first to receive a high-tech new heart valve developed in Australia.

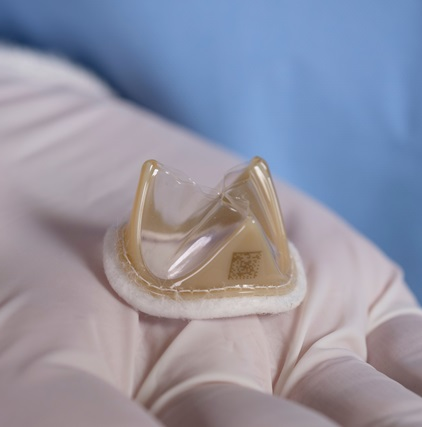

The potentially revolutionary technology, called the Tria heart valve, uses a proprietary CSIRO polymer to create a valve capable of lasting decades without calcification, risk of clotting, or damage to red blood cells.

It is the first time an aortic heart valve made of polymer has ever been implanted in a patient.

The patient is recovering well following the operation in July.

Aortic valve disease is a congenital or age-related condition where the valve between the main pumping chamber of the heart and the body’s main artery stops functioning properly.

The Tria heart valve combines a patented design with CSIRO’s biopolymer material, LifePolymer™.

Beyond heart valves, the next-generation polymer has other potential uses such as coatings for stents, vascular grafts or synthetic membranes for repair of ear drum ruptures.

CSIRO’s Deputy Director of Manufacturing, Dr Paul Savage, said the Tria heart valve is the latest in a long list of innovative polymers developed by CSIRO.

“From polymer bank notes and extended wear contact lenses to life-changing biomedical applications like Elast-Eon™ which is used in cardiac pace makers implanted in over 10 million people worldwide, CSIRO uses innovative new materials to solve the greatest challenges,” Dr Savage said.

The CSIRO team is in discussion with potential industry and research partners to translate the technology into further applications.

Print

Print