3D-Printing makes big leap from light bed

An incredible new technique could be the next big advance in 3D-printing.

An incredible new technique could be the next big advance in 3D-printing.

It allows objects to rise fully-formed out of a liquid base, continuously rather than built layer by layer.

The technique can produce ready-to-use products at a rate 25 to 100 times faster than other methods, while also allowing previously unachievable shapes and forms.

The technology is called CLIP - Continuous Liquid Interface Production.

It manipulates light and oxygen to form and fuse objects while still in liquid form.

It is the first 3D printing process to use tunable photochemistry instead of the layer-by-layer extrusion approach that has defined the technology until now.

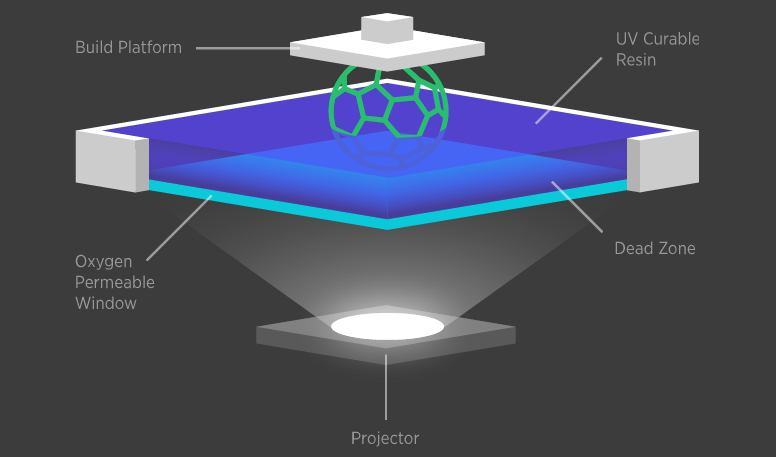

It works by projecting beams of light through an oxygen-permeable window into a liquid resin.

Using the special window that is transparent to light and permeable to oxygen, much like a contact lens, the oxygen flowing through the window can be controlled to create a “dead zone” - a thin layer of uncured resin between the window and the object.

A continuous sequence of UV images is projected through the window and onto the resin, while the object is being drawn up and out of the resin bath.

The CLIP approach can create objects with feature sizes below 20 microns; less than a quarter of the width of a piece of paper.

The CLIP approach can create objects with feature sizes below 20 microns; less than a quarter of the width of a piece of paper.

It also enables the use of a very wide range of materials to make 3D parts with exciting properties, including elastomers, silicones, nylon-like materials, ceramics and biodegradable materials.

CLIP has been developed by Silicon Valley start-up, Carbon3D Inc, which is a commercial spin-off from initial research at the University of North Carolina.

Dr Joseph DeSimone, a professor of chemistry and of chemical engineering, says there are potential uses in virtually all fields of manufacturing.

The potential medical applications alone are profound.

“In addition to using new materials, CLIP can allow us to make stronger objects with unique geometries that other techniques cannot achieve, such as cardiac stents personally tailored to meet the needs of a specific patient,” said DeSimone.

“Since CLIP facilitates 3D polymeric object fabrication in a matter of minutes instead of hours or days, it would not be impossible within coming years to enable personalized coronary stents, dental implants or prosthetics to be 3D printed on-demand in a medical setting.”

A detailed report on the technique - Continuous liquid interface production of 3D objects - is available in the journal Science.

Carbon3D Inc has provided the following video to demonstrate the somewhat mind-boggling technique.

Print

Print